R & D

1. Innovation and patent:

1. Innovation and patent:

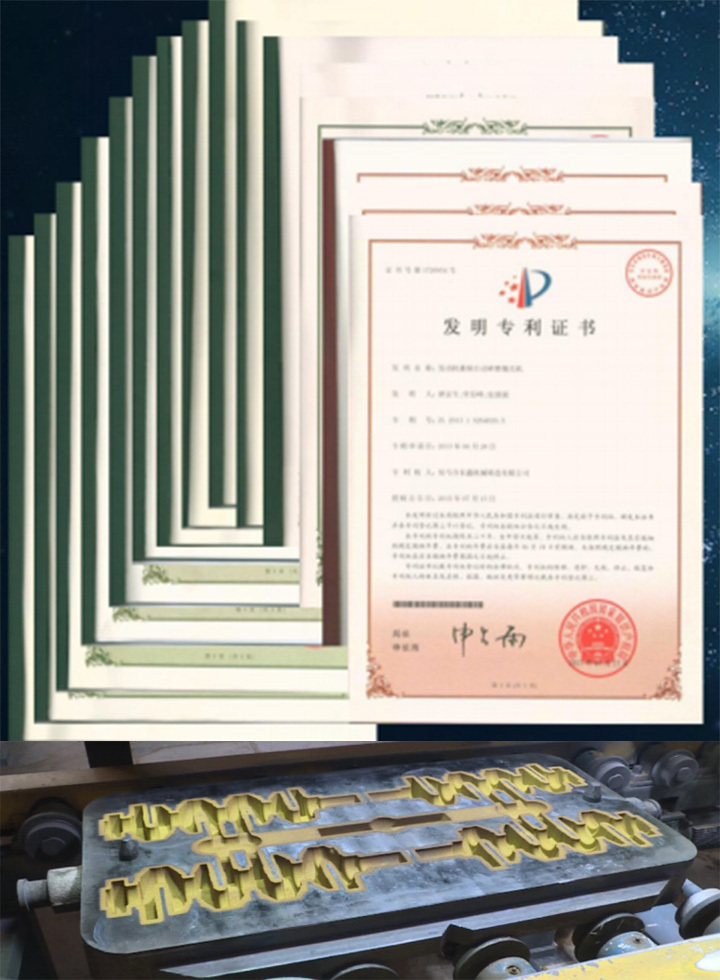

The company has formulated a reward system for small reforms and technological innovation for employees, focusing on stimulating employees' enthusiasm for innovation, relying on innovation mechanisms, and establishing innovative enterprises. It has 7 invention patents, 30 utility model patents, and more than 30 patents under application for approval. There are 10 technical research projects in progress.

2, iron type sand coating process characteristics:

Iron-type sand-coated casting process: it is a process in which a layer of resin sand is applied to the inner cavity of a metal type (iron type) to form a casting mold, which has the characteristics of metal type and shell type casting. Its technological characteristics are: good casting surface finish, high dimensional accuracy, small machining allowance and low processing cost; Due to the rapid crystallization and cooling speed of the casting, the grain size of the casting is refined. At the same time, due to the rigidity of the iron type, the graphitization expansion of ductile iron in the solidification process can be effectively utilized, so that the internal structure of the casting is dense, the shrinkage and shrinkage tendency are reduced, the mechanical properties are significantly improved, and the wear resistance is good, high insurance coefficient and long service life.

3, iron type sand coating process production of ductile iron castings continuous research:

The company focuses on the iron mold sand-coated casting process of intermediate frequency electric furnace smelting + iron mold sand-coated molding + heat treatment strengthening. in addition to the accurate control of the five major elements (c: 0.04, si: 0.06, Mn: 0.05, s:<0.01, p:<0.035), with years of sharpening, in the use of Ni, Sb, Cr and other trace elements, the formation of Dongxin Company's unique hot metal distribution ratio technology, product materials can be stable to meet the QT800-3, QT850-5, QT900-5 high performance requirements.