Production process

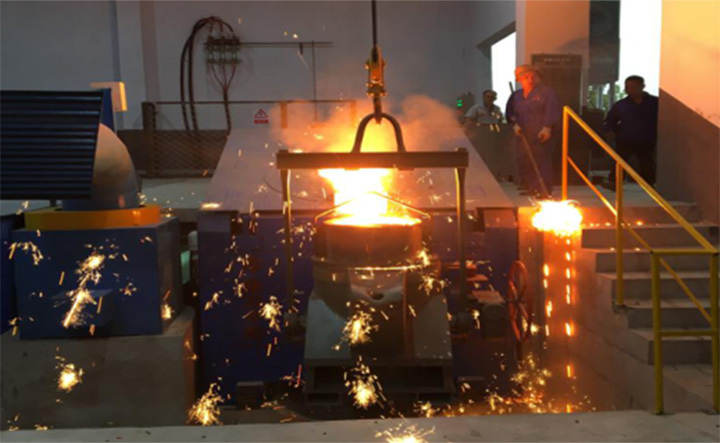

1. Smelting process:

We have 1 tons of medium frequency melting furnace 7 sets. About 45 minutes to melt 1 furnace of molten iron, smelting materials, mainly pig iron, recycled materials and scrap steel, accessories are ferrosilicon alloy, nodulizer, etc. The smelting equipment is equipped with complete environmental protection facilities to effectively recycle, remove dust and discharge smoke and dust.

2. Modeling process:

The automatic molding iron type sand coating production line is adopted, of which 4 are currently in use and 1 is under construction for the automatic molding iron type sand coating production line for commercial vehicle calipers.

|

Dust removal equipment |

25000m³/h |

|

VOC dust removal equipment |

65000m³/h |

|

Iron mould sand coating automatic molding production line |

1200-1300/100-130 |

|

Flat conveyor PS650 1 set |

PS650 |

|

Pair picking manipulator L = 4500 |

L=4500 |

3. Automatic grinding and cleaning process

The automatic grinding casting cleaning production line is adopted to effectively remove casting burrs and improve the consistency of product appearance.

4. Machining line

Since 2005, crankshaft products have been processed internally, from single-cylinder crankshaft to multi-cylinder crankshaft. For many years, we have accumulated rich crankshaft processing experience, have many professional testing equipment, and provide crankshaft development and testing sites for OEMs. Processed product weight range 2kg-50kg.

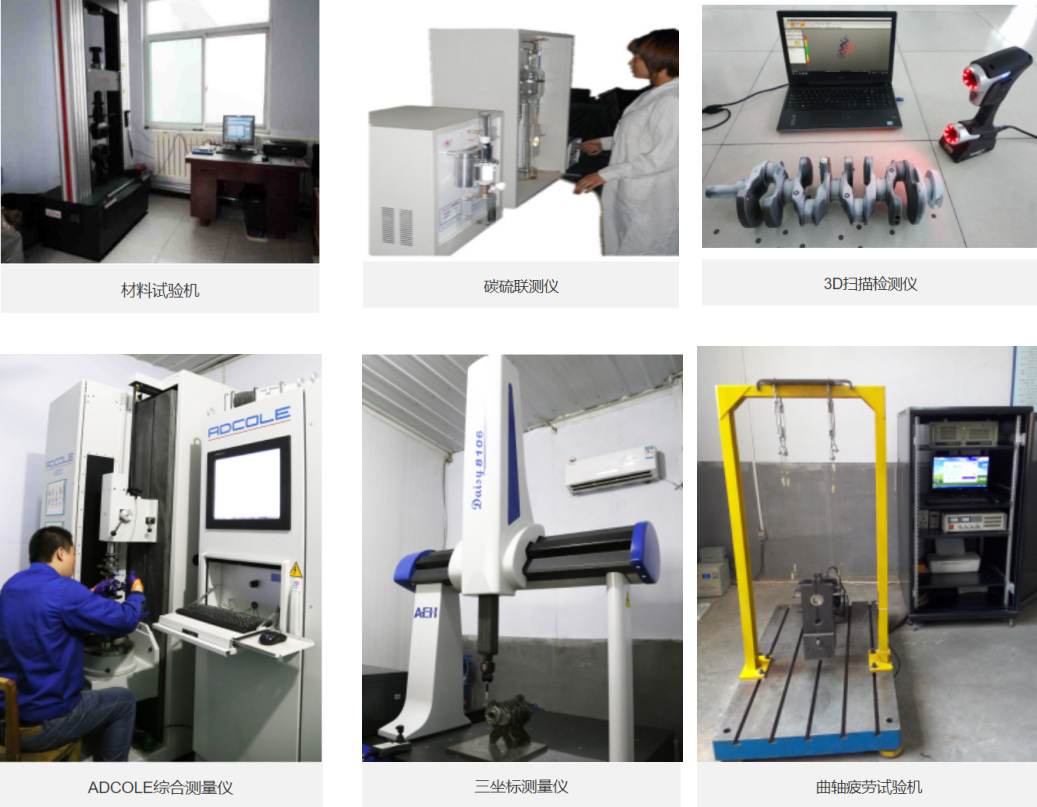

5. Testing

We have advanced testing equipment in smelting and testing instruments to provide accurate data for production to ensure product quality. In the product through high-precision testing instruments on the casting metallographic and mechanical properties of testing, to provide customers with high-quality products.